| Suzuki Environmental Vision 2050 | Milestone 2030 | ||

|---|---|---|---|

| Climate change | CO2 emitted from products | Reduce CO2 emitted from new automobiles by 90% on a Well-to-Wheel basis compared to FY2010 by 2050. | Reduce CO2 emitted from new automobiles by 40% on a Well-to-Wheel basis compared to FY2010 by 2030. |

| CO2 emitted from business activities | Reduce CO2 from business activities by 80% in terms of carbon intensity per sales unit compared to FY2016 by 2050. | Reduce CO2 from business activities by 45% in terms of carbon intensity per sales unit compared to FY2016 by 2030. | |

Basic policy

Recently, extreme weather events said to be caused by global warming have been occurring frequently. To mitigate these climate change effects, the Paris Agreement was adopted to attain net zero greenhouse gas emissions in the second half of this century, with the aim of limiting the rise in global average temperature to less than 2°C relative to pre-industrial levels. Based on the principles of “Sho-Sho-Kei-Tan-Bi (Smaller, Fewer, Lighter, Shorter, Beauty),” Suzuki has long manufactured products with low CO2 emissions using manufacturing methods that emit low CO2 emissions. We acknowledge that we must now strive to reduce CO2 emissions further in order to meet the so-called 1.5°C target. With this in mind, Suzuki will establish emissions reduction targets aligned with climate science and push ahead with related efforts.

Carbon neutrality achievement targets

JapanEurope – 2050

India – 2070

Suzuki aims to achieve carbon neutrality by 2050 in Japan and Europe and by 2070 in India, based on the target dates set by the governments of each country.

We will continue our efforts to achieve carbon neutrality targets for each region, based on the concept of expanding customer choices and delivering products and services that meet local needs.

Disclosure based on the TCFD’s recommendations

Governance

Organizational structure related to climate change risks and opportunities

Suzuki has established the Committee for Carbon Neutrality and Environmental Committee under the Board of Directors for the purpose of the Group’s overall environmental management.

The Board of Directors instructs and supervises the Committee for Carbon Neutrality and Environmental Committee, receives reports from both committees and is the ultimate decision-making body.

The Committee for Carbon Neutrality focuses on the theme of climate change (carbon neutrality) and holds intensive monthly deliberations on decarbonization so the committee can operate more flexibly.

The Environmental Committee meets twice yearly and discuses environment-related themes other than carbon neutrality, such as air conservation, water resources and resource circulation.

Clearly defining the themes of the two committees enhance their effectiveness and further accelerates decision-making toward decarbonization.

- * A subcommittee of the Environmental Committee had previously deliberated on climate change, but in April 2023 this was reorganized as the Committee for Carbon Neutrality and developed as one of the executive and business operations committees.

■Organizational structure related to climate change risks and opportunities

Strategy

Alignment with the TCFD’s recommendations

In April 2020, Suzuki became a signatory to the Task Force on Climate-related Financial Disclosures (TCFD)* in support of its intent. Along with promoting information disclosure in a manner easily comprehensible to stakeholders, we will work to improve the level of sophistication of our scenario analysis and enhance the content of information to be disclosed in order to further increase our resilience against climate change.

* Established in 2015 by the Financial Stability Board (FSB), an international organization to ensure the stability of the financial market.

Climate-related risks and opportunities, scenario analysis

Suzuki has been identifying business risks and opportunities to promote business activities in a sustainable manner. Since the impact of climate change, in particular, is intrinsically uncertain, we believe that it is crucial to assess the degree of its impact on risks and opportunities from a broader future perspective and respond appropriately.

Based on this recognition, we have evaluated differences in the impact of climate change on risks and opportunities by using two scenarios. One is the “4°C scenario” in which climate change causes marked physical effects, and the other is the “1.5°C/2°C scenario” in which mitigation measures are being implemented at an accelerated pace toward the realization of the Paris Agreement. In assuming these scenarios, we have referred to externally developed scenarios that are based on the scientific knowledge of the IEA*1, IPCC*2, and other organizations.

- *1 IEA: International Energy Agency

- *2 IPCC: Intergovernmental Panel on Climate Change

Climate-related risks and opportunities for Suzuki

As more stringent laws and regulations, including emission gas, CO2, and fuel efficiency regulations, are being adopted as mitigation measures against climate change, the resulting increase in development expenses needed to comply with these regulations may greatly impact Suzuki’s business performance. On the other hand, small cars, which are a strength of Suzuki, require less materials and energy to produce and emit less CO2 while in use. We believe that we can create opportunities by leveraging such a unique strength of Suzuki and by handling risks appropriately.

Moreover, from the current fiscal year we have started financial impact analysis based on the scenario analysis related to climate change that we have disclosed. The purpose of this is to reduce and avoid natural disaster risks and enable us to continue our business through assessments of the impact of natural disaster risks such as typhoons, floods, and high tides caused by global warming. We carried out our initial impact assessment on Company sites in Japan and India in addition to domestic primary suppliers.

We will continue to hold careful discussions to reduce or avoid risks caused by climate change, capture opportunities for the future, and increase our competitive edge, and we will incorporate the outcomes of these discussions into our business strategies.

Suzuki’s climate-related risks and differences in impact by scenario

Details of particularly significant risks, creation of opportunities, and status of Suzuki’s response

| Risks | Opportunities | Status of Suzuki’s response | |

|---|---|---|---|

| (1) More stringent CO2 and fuel efficiency standards for automobiles |

|

|

|

| (2) Implementation or reinforcement of carbon tax and other systems |

|

|

|

| (6) More frequent and severe natural disasters |

|

|

|

Risk management

Risk management system

The Corporate Governance Committee deliberates on issues that arise or are recognized in each department and identifies and ascertains potential risks, not limiting itself to just climate-related issues. For environment-related risks, either the Committee for Carbon Neutrality or Environmental Committee conducts intensive examination depending on the theme, and instructs or manages departments.

Themes handled by respective meeting bodies

- Corporate Governance Committee

Ascertains risks arising or recognized in each department, deliberates and issues instructions to the department to resolve the issue. - Committee for Carbon Neutrality

Of environment-related risks, deliberates the risks and opportunities related to climate change (carbon neutrality) and resolves and promotes them. - Environmental Committee

Deliberates on environment-related risks and opportunities apart from climate change, such as water resources and biodiversity, and resolves and promotes them.

Envisaged risks related to climate change

For climate change-related risks, we assess risks and their impact under the two scenarios of the “1.5°C/2°C scenario” and the “4°C scenario.” Regarding the types of risks, we observe risks and their impact from the viewpoints of two types, “transitional risks” from policies, regulations, etc., and “physical risks,” from natural disasters, etc.

| Type of risk | Examples of impacts envisaged | |

|---|---|---|

| Transitional risks | Policies, regulations, and technologies | Payment of fines and loss of sales opportunities, etc., due to regulatory non-conformance due to more stringent CO2 and fuel efficiency standards for automobiles |

| Increase in operating costs, etc., due to implementation or reinforcement of carbon tax and other systems | ||

| Reputation | Decline in corporate value, etc. due to changes in consumer preference and investor behavior | |

| Physical risks | Chronic | Increase in energy costs, etc. due to rise in the average temperature |

| Disruptions in the supply chain, increase in production costs, etc. due to changes in water resource risk | ||

| Acute | Business sites sustaining disaster damage, suspension of business activities, etc. due to more frequent and intensifying natural disasters | |

Indicators and targets

Basic policy

Recently, irregular weather phenomena caused by global warming have been occurring more frequently. The Paris Agreement, which aims to limit the increase in global average temperature to less than 2°C above pre-industrial levels and to achieve virtually zero greenhouse gas emissions in the second half of this century, as adopted to suppress the impact of this climate change.

Suzuki has for a long time continued to make products with lower CO2 emissions during manufacture and during use in line with the philosophy of “Sho-Sho-Kei-Tan-Bi,” and to achieve the so-called 1.5°C target has set reduction targets aligned with climate science and promotes efforts with the awareness of the issue requiring a need to further reduce CO2 emissions.

Moreover, emerging countries also need to think about economic growth and not just climate change measures. Suzuki will aim for growth together with emerging countries and promote climate change measures while working to enrich the lives of people in emerging countries.

Suzuki has set multiple climate-related targets and indicators, and promotes these and manages their progress.

Indicators have been set for such matters as CO2 emissions, climate change and related energy, air conservation and water resource conservation. Indicators have been set in three broad areas related to targets and we aim to achieve each of these goals.

Three major indicators have been set according to their timeframe, and we aim to achieve each target.

- Long-term: Suzuki Environmental Vision 2050

- Medium-term: Milestone 2030

Growth Strategy for FY2030 - Short-term: Suzuki Environmental Plan 2025

Please refer to Environmental Initiatives for details on indicators and targets.

Efforts regarding product use

Disclosure of GHG emissions in the entire value chain

Suzuki believes that for reducing greenhouse gas (GHG) emissions released through overall business activities, including procurement of materials/parts, manufacturing of vehicles and sale of final products, it is important to know and disclose the emissions from those activities. Therefore, we have been making efforts to quantify the emissions of GHG resulting not only from major business activities, but also from the entire value chain*1 since FY2013.

CO2 emissions generated through the entire value chain during FY2022 stood at 103.70 million t-CO2, of which the emissions falling under Scope 3 (indirect emissions from other activities)*1 were 102.56 million t-CO2 that include 82.70 million t-CO2 classified into Category 11 (Use of products sold by Suzuki)*2 accounting for 79.7% of the total emissions through the overall value chain.

Recognizing that it is very important to reduce the CO2 emissions released through the use of our products for reducing the total GHG emissions in the entire value chain, we will make continuous efforts to emphasize improvement of fuel efficiency during product development and improvement.

- *1 Value chain: A method of systematizing how a series of business activities go into the creation of its ultimate value. Calculations are composed of Scope 1, Scope 2, and Scope 3 in accordance with the calculation standard, GHG Protocol*3. The business activities in a value chain include parts and materials procurement, manufacturing, delivery, sales and customer services, as well as administrative work and engineering development work that support these activities. We have been participating in Green Value Chain Platform*4 operated by the Ministry of the Environment and the Ministry of Economy, Trade and Industry since FY2014 and introducing our efforts in quantifying GHG emissions.

- *2 Category 11: This indicates the life cycle GHG emissions from Suzuki’s products sold in the fiscal year.

- *3 GHG Protocol: This is a method to develop calculation and reporting standards for greenhouse gases (GHG) led by the World Resources Institute (WRI), a global environmental think tank based in the U.S., and the World Business Council on Sustainable Development (WBCSD), a conglomeration of companies aiming for sustainable development.

- *4 Green Value Chain Platform: This is an information platform related to value chain emissions operated by the Ministry of the Environment and the Ministry of Economy, Trade and Industry to provide various kinds of information such as domestic and overseas trends and calculation methods, etc. regarding global warming.

Website: http://www.env.go.jp/earth/ondanka/supply_chain/gvc/en

Breakdown of FY2022 GHG emissions

Total GHG emissions released from the value chain: 103.70 mil. t-CO2

[Calculation range] Suzuki Motor Corporation and 66 domestic and 32 overseas manufacturing and non-manufacturing subsidiaries

[Calculation period] From April 2022 to March 2023

Classification of Scopes 1 and 2 and categories of Scope 3 quantified by Suzuki

- * Category 8 (Leased assets (upstream)) is excluded because it is included in Scope 1 and 2. Category 10 (Processing of sold products), Category 13 (leased assets (downstream)), Category 14 (Franchises) and Category 15 (Investments) are not included as they are not part of the calculation.

GHG emissions in the entire value chain

Scope 1, 2, and 3

Third party guaranteed items are marked with ✓

(10,000 t-CO2)

| FY2020 | FY2021 | FY2022 | ||

|---|---|---|---|---|

| Entire value chain (total of Scope 1, 2, and 3) | 9,018 | 9,207 | 10,370 | |

| Direct emissions from corporate activities (Scope 1*1) | 38 | 40 | 42 | |

| Domestic | 15 | 15 | 15 | ✓ |

| Overseas | 23 | 25 | 27 | |

| Indirect emissions from energies (Scope 2*1) | 68 | 71 | 72 | |

| Domestic | 29 | 26 | 28 | ✓ |

| Overseas | 38 | 45 | 45 | |

| Emissions from corporate activities (total of Scope 1 and 2) | 105 | 111 | 114 | |

| Emissions from use of products by users (Scope 3: Category 11)*2 | 7,573 | 7,532 | 8,270 | ✓ |

| Other emissions (other than Scope 3: Category 11) | 1,339 | 1,564 | 1,986 | |

| Other indirect emissions (total of Scope 3) | 8,913 | 9,096 | 10,256 |

- *1 <Scope 1 and 2>

- ●Calculation range

- −Domestic: Suzuki Motor Corporation and 66 domestic manufacturing and non-manufacturing subsidiaries

- −Overseas: 32 overseas manufacturing and non-manufacturing subsidiaries

- ●Target gases: Greenhouse gases (seven gases: carbon dioxide, methane, dinitrogen monoxide, hydrofluorocarbons, perfluorocarbons, sulfur hexafluoride, nitrogen trifluoride)

- ●Emission coefficients

- −Electricity: The most recently adjusted emission coefficient by electricity provider for Japan, and IEA Emissions Factors 2022 for overseas

- −Fuel: Emission coefficients under Japan’s Mandatory Greenhouse Gas Accounting and Reporting System were used in Japan, and IPCC Guidelines 2006 were used overseas.

Unit calorific values for city gas are those released by suppliers.

- ●Calculation range

- *2 <Scope 3 Category 11>

- ●Calculation range: Suzuki Group

- ●Products subject to calculation: Automobiles, motorcycles, outboard motors, motorized wheelchairs, and other Suzuki products

- ●Outline of calculation method

- −Calculated by multiplying the estimated lifetime running distance of products sold in the fiscal year under review by the emissions intensity for each model.

- −Annual running distance and years of use are based on published information, primarily the IEA SMP Model.

- −Emissions intensity for each model are based on the certified values prescribed by the regulations of each country and converted to WTW (Well-to-Wheel).

* Data for FY2021 and earlier have been revised retrospectively in accordance with the revision to the calculation method.

Power consumption amount of Suzuki Group

(GWh)

| FY2020 | FY2021 | FY2022 | |

|---|---|---|---|

| Global total | 3,058 | 3,265 | 3,455 |

| Domestic | 1,381 | 1,327 | 1,360 |

| Overseas | 1,677 | 1,938 | 2,095 |

Calculation range: Suzuki Motor Corporation and 66 domestic and 32 overseas manufacturing and non-manufacturing subsidiaries

(includes consumption of renewable energies generated within sites)

Calculation of CO2 emissions of products using Life Cycle Assessment (LCA)

In order to understand the environmental impact of our products, Suzuki adopts the Life Cycle Assessment (LCA)*1 that assesses products with specific figures not only during their running stage but throughout their whole life cycle from raw material production to disposal. The Company is promoting reduction of environmental load by utilizing their results*2 for product development*3 and business activities.

- *1 Life Cycle Assessment is a method to calculate and evaluate the overall potential environmental impact of a product at each stage of its life cycle, from raw material production to disposal.

- *2 Evaluation results are shown as an index in order to check the relative environmental improvement effect.

- *3 Most CO2 emissions from automobiles occur during the running stage. Suzuki is promoting R&D to reduce CO2 emissions during the running stage. One example of this is the Swift, whose hybrid technology reduces CO2 emissions by approximately 4.3% compared to previous models.

Suzuki LCA Stages

Ratio of CO2 emissions of Suzuki vehicles by lifecycle stages

- * Since fuel efficiency testing mode was changed from JC08 to WLTC in October 2018, Hustler only shows the results of new models.

- * Result of a vehicle’s lifetime running distance of 110,000 km (13 years) driven in each mode.

- * Running stage takes production of replacement parts into consideration, including tires, engine oil, and batteries.

Ratio of CO2 emissions by each model

- * Result of a vehicle’s lifetime running distance of 110,000 km (13 years) driven in JC08 mode and WLTC mode.

- * “H” represents Hybrid vehicles and “MH” represents Mild Hybrid vehicles.

Efforts for design and development

Efforts for next-generation vehicles

Development of electric vehicles

Suzuki is developing electric vehicles tailored to the conditions of each country around the world and the way that customers use them toward the realization of carbon neutrality and all-electric. At the Auto Expo 2023 show held in India in January 2023, we unveiled the eVX, our first global strategic electric vehicle concept model, planned for commercialization by 2025. Moreover, in an exhibition event for the G7 Hiroshima Summit held in May 2023, we unveiled the prototype of a commercial minivan electric vehicle equipped with a BEV system that was jointly developed with collaborating companies.

Auto Expo 2023 in India

A commercial minivan electric vehicle unveiled at the G7 Hiroshima Summit held from May 18 to 21, 2023

Efforts for motorcycles

Suzuki developed e-BURGMAN, a demonstration vehicle that can be equipped with a replaceable battery (Honda Mobile Power Pack) operated by Gachaco. We conducted a demonstration experiment using this electric scooter from April to June 2023 in Tokyo.

We plan to conduct a demonstration experiment in Osaka going forward, and using data collected in these experiments, such as how they are used and user needs, will develop electric motorcycles in the future.

e-BURGMAN, a demonstration vehicle electric scooter

Efforts for outboard motors

For small outboard motors that are often used in lakes and rivers, we will introduce battery EVs in FY2024. We plan to launch five models by FY2030, and plan for a battery EV ratio of 5%. For large outboard motors used in the ocean, we are considering adopting carbon neutral fuels.

R&D expenses, capital expenditures

For the development of carbon neutral and advanced safety technologies we plan to invest ¥2 trillion in R&D and ¥2.5 trillion in capital expenditures, a total of ¥4.5 trillion by FY2030. Of the ¥4.5 trillion, ¥2 trillion will be electrification-related investments, of which ¥500 billion will be battery-related investments.

For R&D investment, ¥2 trillion is planned for domains including carbon neutrality such as electrification and biogas, as well as autonomous driving. In addition, we plan to invest ¥2.5 trillion for capital expenditures in facilities including construction of a BEV plant and renewable energy facilities.

Investment of resources from FY2023 to FY2030

TopicsSuzuki signed agreement for co-development of 2-speed EV transmission with Canada’s Inmotive

Suzuki signed a joint development agreement with Inmotive Inc. (Headquarters: Ontario, Canada; CEO: Paul Bottero; hereinafter “Inmotive”) for the development of a 2-speed EV transmission for a future Suzuki electric vehicle.

Inmotive was founded in 2010 in Toronto, Canada. It developed the IngearTM 2-speed transmission, a lightweight, compact, and efficient technology to enhance the performance of EV powertrain units. Inmotive aims to accelerate the global evolution to affordable zero-emission mobility and play an important role in mitigating climate change.

With this joint development agreement for the 2-speed EV transmission, Suzuki believes that it has the possibility of extending electric vehicle range through efficient use of motor torque while also lowering costs due to using a smaller electric powertrain unit and improving driving performance in various driving scenes.

Suzuki will continue to build relationships with companies that possess unique technologies, to accelerate the development of next generation mobility and provide a variety of transport solutions that will benefit people and society.

Overview of Inmotive

| Company name | Inmotive Inc. |

|---|---|

| Headquarters | Toronto, Ontario, Canada |

| Representative (CEO) | Paul Bottero |

| Established | 2010 |

| Business overview | Development of 2-speed EV transmission |

| Website | https://www.inmotive.com/ |

TopicsSuzuki concludes agreement for co-development of autonomous electric vehicle platform with Applied EV

Suzuki signed a memorandum of understanding with Applied Electric Vehicles Ltd (Headquarters: Victoria, Australia, CEO: Julian Broadbent; hereinafter “Applied EV”) for the development of an autonomous EV platform.

Applied EV is an Australian technology company with strengths in software and electronics for autonomous ready vehicles. Suzuki entered into an agreement in September 2021 and invested in Applied EV in 2022, and has since been evaluating the possibility of collaboration.

In the co-development project, Applied EV’s autonomous vehicle platform, Blanc RobotTM, will be integrated to the ladder frame of Suzuki’s 4WD Jimny, electrified by Applied EV and controlled by their central control system, Digital BackboneTM. The two companies intend to bring the Blanc RobotTM to production and develop business models to expand the adoption of autonomous electric vehicles and enhance brand awareness.

Overview of Applied Electric Vehicles

| Headquarters | Melbourne, Victoria, Australia |

|---|---|

| Business overview | Software development and supply in the mobility field |

| Representative (CEO) | Julian Broadbent |

| Established | 2015 |

| Website | https://www.appliedev.com |

Generation 5 Applied EV’s Blanc RobotTM

TopicsSuzuki conducted a demonstration experiment in Tokyo using the e-BURGMAN electric scooter

Suzuki conducted electric scooter demonstration tests in Tokyo from April 2023 using (swappable) batteries standardized by the Swappable Batteries Motorcycle Consortium and the swappable battery sharing service provided by Gachaco (CEO Kazunari Watanabe).

The objective of the demonstration test was to evaluate and ascertain requests for improvements to type-2 motor scooter electric scooters with swappable batteries, and was conducted mainly in the Jonan area of Tokyo (Meguro, Shinagawa, Ota, and Minato wards), where Gachaco swappable battery stations have been installed.

Suzuki will gather data needed for those using motorcycles as transport in their daily lives or work, such as commutes to work or school, or for shopping, and will lead to electric motorcycle development in the future.

e-BURGMAN, a demonstration vehicle electric scooter

Overview of the demonstration test

| Test period | April to June 2023 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test area | Jonan area of Tokyo (where Gachaco swappable battery stations have been installed) | ||||||||||||||||||

| Based used | Suzuki World Setagaya Minami (dealer directly operated by Suzuki Motorcycle Sales Inc.) | ||||||||||||||||||

| Vehicle used | e-BURGMAN, a demonstration vehicle electric scooter (type-2 motor scooter) | ||||||||||||||||||

| Vehicle specifications |

|

||||||||||||||||||

| Number of vehicles used | 8 | ||||||||||||||||||

| User | Authorized people from Suzuki Motorcycle Sales Inc. and customers using motorcycles provided by Suzuki Motorcycle Sales Inc. |

TopicsApproval granted to establish HySE research body for development of hydrogen small mobility engines

—Start research activities for development and popularization of hydrogen small mobility engines toward achievement of a decarbonized society—

Suzuki, Kawasaki Motors, Ltd. (hereinafter “Kawasaki Motors”), Honda Motor Co., Ltd. (hereinafter “Honda”), and Yamaha Motor Co., Ltd. (hereinafter “Yamaha Motor”) jointly announced on May 11, 2023, that they received approval from the Ministry of Economy, Trade and Industry to form a technological research association called HySE (Hydrogen Small mobility & Engine technology) for developing hydrogen-powered engines for small mobility.*

To realize a decarbonized society, a multi-pathway strategy to address various issues in the mobility sector is necessary, rather than focusing on a single energy source. Against this backdrop, research and development targeted at commercialization of mobility with engines powered by hydrogen—deemed a next-generation energy source—is gaining momentum. However, the use of hydrogen poses technical challenges, including fast flame speed and a large region of ignition, which often result in unstable combustion, and the limited fuel tank capacity in case of use in small mobility vehicles. In addressing these issues, the members of HySE are committed to conducting fundamental research, capitalizing on their wealth of expertise and technologies in developing gasoline-powered engines, and aim to work together with the joint mission of establishing a design standard for small mobility’s hydrogen-powered engine, and of advancing the fundamental research endeavors in this area.

The members of HySE will continue to deepen their collaborative relations in order to provide a variety of small mobility options to users and meet their diverse needs, thereby contributing to the realization of a decarbonized society.

In addition to the full members (the four aforementioned motorcycle manufacturers), Kawasaki Heavy Industries, Ltd. (hereinafter “Kawasaki Heavy Industries”) and Toyota Motor Corporation (hereinafter “Toyota”) support the association as special members. Kawasaki Heavy Industries, being one of the main organizers of the “CO2-free Hydrogen Energy Supply-chain Technology Research Association” (hereinafter “HySTRA”), will drive forward HySE’s activities, based on the knowledge gained from its activities for HySTRA. Toyota, on the other hand, will assume the role of leveraging HySE’s research results to the maximum benefit for the development of hydrogen-powered engines, utilizing its know-how on experiments, analyses, and the designing of large hydrogen-fueled power units for four-wheel vehicles.

●Main research and development areas, and the role of each company

- Research on hydrogen-powered engines

Research on the model-based development of hydrogen-powered engines (Honda)

Element study on functionality, performance, and reliability of the hydrogen-powered engines (Suzuki)

Hands-on research using real hydrogen-powered engines on their functionality, performance, and reliability (Yamaha Motor, Kawasaki Motors) - Study on hydrogen refueling system

Studying the requirements for a hydrogen refueling system and hydrogen tanks for small

mobility (Yamaha Motor) - Study on fuel supply system

Studying the auxiliary equipment required for a fuel supply system and tanks, and the equipment installed between the fuel tank and the injector (Kawasaki Motors)

●Overview of HySE (planned)

| Name | Hydrogen Small mobility & Engine technology (HySE) |

|---|---|

| Address | Yaesu Central Tower, 2-2-1 Yaesu, Chuo-ku, Tokyo |

| Candidate chair | Kenji Komatsu (Executive Officer, Yamaha Motor Co. Ltd.) |

| Candidate members | Regular Members: Suzuki, Kawasaki Motors, Honda and Yamaha Motor Special Members: Kawasaki Heavy Industries and Toyota |

| Date of establishment | June 2023 |

- * Motorcycles, mini vehicles, small marine vessels, construction equipment, drones, etc.

Efforts to produce automobile batteries domestically in India

In India, addressing the environment is a crucial issue and there needs to be a spread of electrified vehicles affordable for customers. Suzuki along with Toshiba Corporation, and DENSO CORPORATION established the lithium-ion battery manufacturing company, TDS Lithium-Ion Battery Gujarat Private Limited (TDSG), to build India’s first dedicated automobile lithium-ion battery cell and pack production plant at a supplier park adjacent to Suzuki Motor Gujarat’s automobile plant in Gujarat. Production started in 2021 and they are being supplied to Suzuki manufacturing plants within and outside of India, including Maruti Suzuki India Limited.

In addition, the plant covers part of its necessary electricity generated through solar panels installed on its roof as one effort to address the pursuit of carbon neutrality.

Going forward, Suzuki will contribute to improving the environment and to sustainable development in India by expanding battery production in the state of Gujarat, ensuring a stable supply of lithium-ion batteries in India, and promoting the penetration of electrified vehicles (HEVs* and EVs).

* HEV is an acronym of hybrid electric vehicle.

TopicsSuzuki starts exploring collaboration with PowerX, Inc.

—Aim to contribute to the realization of a carbon-neutral society through battery energy storage systems—

Suzuki agreed with PowerX, Inc. (Headquarters: Minato-ku, Tokyo; Director, President & CEO: Masahiro Ito; hereinafter “PowerX”), a company that manufactures and sells battery energy storage systems, to start exploring business partnership opportunities.

Japan and India are faced with common challenges including realization of carbon neutrality through utilizing non-fossil fuel and renewable energy, as well as improvement of energy self-sufficiency. Also, both countries are in need of charging solutions to promote the adoption of EVs in the coming years.

Suzuki and PowerX have agreed and signed a memorandum of understanding to explore possibility of business partnership utilizing battery energy storage systems and ultrafast EV charger in Japan and India. Through this, the two companies aim to contribute to the realization of a carbon-neutral society by expanding the use of renewable energy and promoting the adoption of EVs.

PowerX manufactures, sells and provides services using its proprietary battery products for energy storage, ultrafast EV charging, home and marine applications. Additionally, the company is building its own GW scale battery plant in Okayama Prefecture, which will be among the biggest in Japan.

Suzuki will consider specific details of the collaboration with the aim of becoming a lifestyle infrastructure company that provides solutions based on a broad perspective of not only the products themselves, but also the entire environment related to the products, including the infrastructure and systems where the solutions are applied.

Overview of PowerX

| Company name | PowerX, Inc. |

|---|---|

| Website | https://power-x.jp/en |

| Establishment | March 22, 2021 |

| Representative | Masahiro Ito (Director, President & CEO) |

| Address | Midtown Tower 43F, Akasaka 9-7-1, Minato-ku, Tokyo, Japan |

| Business overview | R&D and production of Power Transfer Vessels and energy storage systems |

Efforts for products

Automobiles

●Global average CO2 emissions of new models*1

- Suzuki has set a new target for the reduction of CO2 emissions, which are considered a factor in climate change, by 30% of the global average CO2 emissions from new vehicles (compared to FY2010 results) for automobile products under the Suzuki Environmental Plan 2025. We continue our environmental conservation efforts.

- The result for FY2022 was a reduction of 25.8% compared to FY2010.

- In promoting the Suzuki Environmental Plan 2025, we aim to further develop and spread electrification technologies and contribute to the reduction of CO2 emissions by achieving the Suzuki Environmental Vision 2050.

Trends in reduction of global average CO2 emissions of new models

*1 Global average CO2 emissions for new models are calculated according to internal regulations based on CO2 emissions (fuel efficiency) measured by the methods specified in each country.

Global new models

Applies to all new cars Suzuki sells globally

CO2 emissions

Consideration given to Well-to-Wheel

●Status of average CO2 reductions in main markets

Status of average CO2 reductions

in Japan*2 (passenger cars)

Status of average CO2 reductions

in India

Status of average CO2 reductions

in Europe

*2 Values converted from 10.15 mode or WLTC mode to JC08 mode

[Japan]

In FY2022, Suzuki worked to reduce CO2 through hybrid specifications for the Escudo and Solio, but the reduction rate remained equal to the previous year due to the impact of production adjustments.

[India]

Compared to FY2021 we achieved a 2% reduction with contributions from the addition of CNG specifications in Ertiga and Baleno, and installation of new engines in Alto, S-Presso, EECO and Brezza.

[Europe]

Compared to FY2021 we achieved a 2% reduction due to improved fuel efficiency in the Vitara.

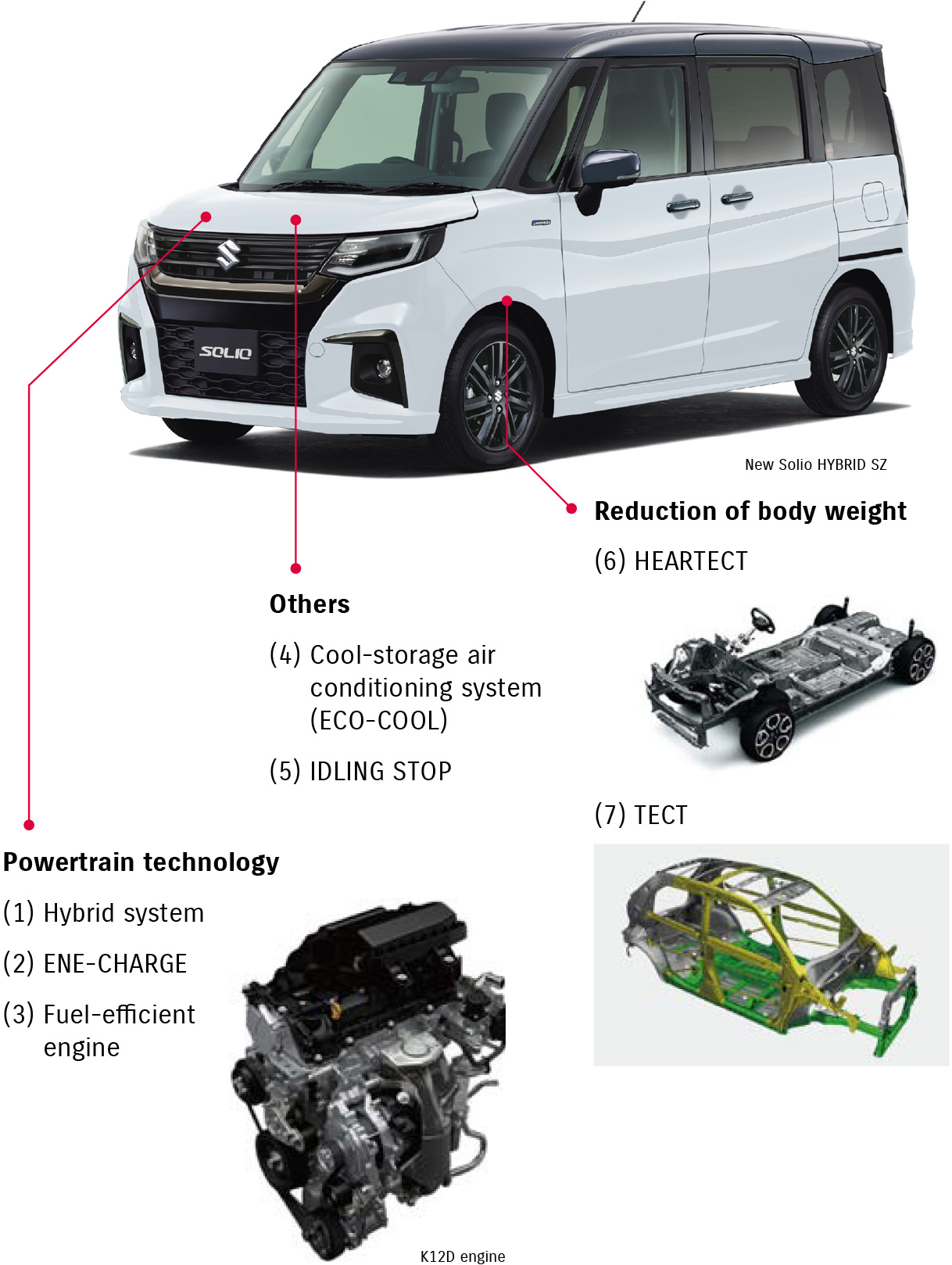

●Major fuel efficiency improvement technology

| Fuel efficiency improvement technology | Outline | Main new models launched in FY2022 | ||

|---|---|---|---|---|

| (1) | Hybrid system | Hybrid system | Compact system that realizes motor assistance and EV driving, and both high fuel efficiency and strong driving. https://www.suzuki.co.jp/car/technology/hybrid/ (Japanese language only) |

|

| Mild Hybrid system | Hybrid system that realizes high fuel efficiency by generating electricity during deceleration and assisting the engine with such electricity upon acceleration. https://www.suzuki.co.jp/car/technology/mildhybrid/ (Japanese language only) |

|

||

| (2) | ENE-CHARGE | Energy generated during deceleration is used to generate electricity with an alternator (generator) to charge the lead battery and lithium-ion battery. The system achieves high fuel efficiency by supplying that power to electric components. https://www.suzuki.co.jp/car/technology/ene-charge/ (Japanese language only) |

|

|

| (3) | High fuel efficiency engine | DUALJET engine | Engine that realizes both power and environmental performances by increasing thermal efficiency through adopting two injectors per cylinder and homogenizing the air-fuel mix. Main engines: K12D, R06D https://www.suzuki.co.jp/car/technology/dje/ (Japanese language only) |

|

| BOOSTERJET engine | Direct-injection turbo engine that realizes high output and torque. Main engine: K14D https://www.suzuki.co.jp/car/technology/bje/ (Japanese language only) |

|

||

| (4) | Cool-storage air conditioning system (ECO-COOL) | System that freezes the freezable substance built in the air conditioning unit with cold air emitted while operating the air conditioner, and maintains cold wind even while sending air in idle-stop mode. https://www.suzuki.co.jp/car/technology/eco-cool/ (Japanese language only) |

|

|

| (5) | IDLING STOP | System that stops the engine automatically when the vehicle speed decreases to a specific level or lower. https://www.suzuki.co.jp/car/technology/idling_stop/ (Japanese language only) |

||

| (6) | HEARTECT | New platform designed by totally changing the major structure and component layout, realizing an improvement in the basic performance and weight reduction. https://www.suzuki.co.jp/car/technology/heartect/ (Japanese language only) |

||

| (7) | TECT | A lightweight shock-absorbing body that achieves both high safety and lighter vehicle weight by using high-strength and lightweight materials. It contributes to high fuel efficiency by reducing the burden on engines through lighter weight. https://www.suzuki.co.jp/car/technology/tect/ (Japanese language only) |

||

Motorcycles

●Global average CO2 emissions of new models

We are striving to improve fuel efficiency and reduce CO2 emissions through the improvement in combustion, reduction of friction loss, and weight reduction.

In FY2022, we achieved 13% reduction (compared to FY2010).

Trends in reduction of global average CO2 emissions of new models

●Major fuel efficiency improvement technology

| Technologies and efforts for fuel efficiency improvement | Outline | Main new models launched in FY2022 | ||

|---|---|---|---|---|

| (1) | Powertrain | SEP-α engine | The engine is a further evolution of the SEP engine that realized low fuel consumption without reducing power through high fuel efficiency and reducing friction loss. An idling stop system that automatically stops the engine when the vehicle comes to a halt, and a silent starter system that quietly starts the engine are incorporated, contributing to excellent environmental performance and quiet starting. |  |

| (2) | Dual-spark technology | Mechanism equipped with two spark plugs per cylinder that contributes to smooth output characteristics, high fuel-efficiency performance, and reduction of exhaust gas emissions by high combustion efficiency. |  |

|

| (3) | Injection system | Injection system equipped with six sensors* and designed to realize optimum control under various conditions and realize both powerful performance and high fuel efficiency.

|

|

|

| (4) | Open-type rectifier | Realized high fuel efficiency with reduced mechanical losses by generating the minimum necessary amount of electricity with magneto. |  |

|

| (5) | Improvement in frame | Optimized wall thickness and cross-sectional shape. |  |

|

| (6) | Eco-driving assistance system | Eco-drive indicator allows the rider to check fuel-efficiency indicator and fuel-efficient driving at a glance. |  |

|

| (7) | LED headlight LED tail lamp |

Aimed to reduce power consumption and increase service life. |  |

|

* Domestic specifications ** Overseas specifications

Outboard motors

●Main fuel efficiency improvement technology

New DF350AMD

●Engine technology

(1) Lean burn control system

(2) Higher compression ratio

(3) Auto trim

| Technologies and efforts for fuel efficiency improvement | Outline | Main new models launched in FY2022 | |||

|---|---|---|---|---|---|

| (1) |

|

System to improve fuel efficiency by automatically producing lean air-fuel mixture in accordance with the engine output so that high-efficiency combustion can be achieved. |  |

||

| (2) | Higher compression ratio | Efforts for improving the cooling of the combustion chamber, reducing the temperature of air flow into the combustion chamber, increasing the compression ratio, and improving thermal efficiency. |  |

||

| (3) |

|

The trim angle is automatically adjusted according to engine revolutions, contributing to a faster top speed and better fuel economy. |  |

●Global CO2 emissions per unit output

Trends in reduction of global CO2 emissions per unit output

●Improved fuel efficiency of new models

The new DF140B, which went on sale in December 2021, achieves up to 10% better fuel efficiency than the previous model through such measures as the adoption of a lean burn control system and higher engine compression ratio.

Fuel efficiency improvement ratio (when previous model is set at 100)

- * The graph shows a comparison based on Suzuki’s internal measurement data. There could be differences depending on conditions (weather, sea conditions, type of boat on which mounted, personnel, etc.).

Other efforts

●Introduction of CNG*1 vehicles

In recent years, concerns about global warming and urban air pollution have been raised in India. Natural gas, which fuels CNG vehicles, is mainly composed of methane (CH4) that emits less CO2 and NOx during combustion compared to oil and coal*2, so Maruti Suzuki India promotes production and sales of CNG vehicles.

- *1 CNG (Compressed Natural Gas)

- *2 Reference: FY 2014 Petroleum Industry Structure Study on the Expansion of Natural Gas Utilization in Light of Recent International Situation, etc. (March 2015), Institute of Energy Economics, Japan. (Translation)

●Converting to refrigerant with low global warming potential

Under the Act on Rational Use and Appropriate Management of Fluorocarbons (Fluorocarbon Emissions Control Act), refrigerants in passenger car air conditioners shipped to Japan are required to convert to a refrigerant with a lower global warming potential from FY2023 onward.

Suzuki has until now used HFC-134a as a passenger car air conditioning refrigerant, but as this has larger global warming potential, we developed HFO-1234yf, a refrigerant that has an extremely low global warming potential, and completed conversion of use to HFO-1234yf in all passenger cars to be shipped to Japan by the end of FY2022.

TopicsConcluding a three-party agreement for the biogas demonstration project in India

—Establish four biogas production plants starting from 2025—

Suzuki concluded a three-party agreement between Suzuki R&D Center India Private Limited, a wholly owned subsidiary of Suzuki in India, National Dairy Development Board (NDDB), and Banas Dairy (Headquarters: State of Gujarat), one of the largest dairy manufacturers in Asia, to set up biogas production plants that would contribute toward realizing carbon neutrality in India.

A contract conclusion ceremony was held in September 2023 at the Embassy of India in Japan, with Banas Dairy’s Chairman Shri Shankar Chaudhry, NDDB’s Chairman and Managing Director Dr. Meenesh C Shah and Suzuki’s President Toshihiro Suzuki attending. Ambassador of India to Japan, His Excellency Mr. Sibi George graced the occasion and conveyed his best wishes.

Suzuki signed an MOU with NDDB and Banas Dairy in December 2022 to start a biogas demonstration project that aimed to make fuel for automobiles by refining methane from biogas generated by fermenting cow dung, and four biogas production plants will be operated starting from 2025 in the Banaskantha district in the state of Gujarat. The total investment for the four plants is planned to be 2.3 billion Indian rupees (approximately ¥4 billion). Also, biogas filling stations will be established alongside each plant, which will distribute fuel for CNG vehicles, in which Maruti Suzuki India holds over 70% market share in India.

President Suzuki said “Suzuki is engaging in reduction of greenhouse gas in ways that suit the situations of each country and region. In India, there is expectation for biogas which is said to have high reduction effects. We will contribute toward realizing carbon neutrality through making proactive initiatives in the biogas production business.”

Efforts in business activities

Efforts in manufacturing

Reduction of CO2 emissions

The Paris Agreement, which is an international framework aimed at reducing greenhouse gas to limit global warming, has been enacted, and governments of various nations and companies worldwide are promoting actions to reduce the emission of greenhouse gases in order to realize the target of limiting the rise of the global average temperature to less than 2°C.

We consider that it is important to globally promote a reduction of CO2 emissions from plants in order to reduce the effects of greenhouse gas emissions, and make efforts to reduce the amount of CO2 emissions per production unit (automobile production units) of Suzuki’s global manufacturing units by 25% (compared to FY2016) by FY2025 in accordance with the Suzuki Environmental Plan 2025.

The total amount of CO2 emissions from manufacturing activities in FY2022 was 1,004,000 t-CO2/year at Suzuki overall on a global scale, 321,000 t-CO2/year in Japan, and 683,000 t-CO2/year overseas. The amount of CO2 emissions per manufacturing unit was 0.313 t-CO2/unit.

As reduction initiatives, aside from activities for saving energy and eliminating waste, Suzuki is working to expand solar power generation and purchase CO2-free electricity both in Japan and overseas.

We will continue to further promote the effective use of energy and work to reduce intensity.

CO2 emission performance at global manufacturing bases

[Scope of aggregation]

Suzuki (Iwata Plant, Kosai Plant, Osuka Plant, Sagara Plant, Hamamatsu Plant, former Takatsuka Plant (until July 2018), and former Toyokawa Plant (until July 2018)), 4 domestic manufacturing subsidiaries, and 15 overseas manufacturing subsidiaries

[CO2 conversion factor]

Fuel (excluding city gas) conforms to 2006 IPCC guidelines and city gas conforms to the values published by Chubu Gas.

Electric power conforms to the Act on Promotion of Global Warming Countermeasures (base emission factors among the values published by power companies) in Japan and varies depending on the values of each year from 2010 to 2019 of IEA 2021 overseas.

CO2 emissions by domestic plants in FY2022

| CO2 emissions (1,000 t-CO2) | |

|---|---|

| Iwata Plant | 28.1 |

| Kosai Plant | 91.4 |

| Osuka Plant | 35.8 |

| Sagara Plant | 78.1 |

| Hamamatsu Plant | 7.4 |

●Energy-saving activities at plants

All employees participate in daily activities such as reducing air leaks, turning off lights during breaks, and switching off power when plants are not in operation. These efforts are steadily producing results each year.

Also, when upgrading the deteriorated production equipment or introducing new equipment for production of new models, we work on building more effective energy-saving plants than ever before by utilizing gravity, downsizing and reducing the weight of equipment, and adopting highefficiency devices such as LED lights and top-runner devices (motors, transformers).

Furthermore, as one of Suzuki’s efforts to reduce CO2, we are reconfiguring our supply of energy, such as by converting fuels from LPG to city gas at the Osuka Plant and Kosai Plant. We will also extend this conversion to the Iwata Plant and Sagara Plant.

The amount of CO2 reduction at domestic and overseas plants and reduction according to activities are shown on the right.

Amount of CO2 reduction according to activities globally

[Scope of aggregation]

Suzuki (Iwata Plant, Kosai Plant, Osuka Plant, Sagara Plant, Hamamatsu Plant, former Takatsuka Plant (until July 2018), and former Toyokawa Plant (until July 2018)) and 15 overseas manufacturing subsidiaries

●Promoting the use of renewable energy

Suzuki promotes the use of renewable energy as an integral part of its global warming countermeasures.

Suzuki is proceeding with the installation of solar power facilities at its domestic plants, which it has been working on from before, and has introduced these facilities on land adjacent to the Sagara Plant (Makinohara) as well as at the Hamamatsu Maisaka-Nishi Solar Power Plant, and Hamamatsu Plant. We also partially began solar power generation at the Iwata Plant in 2021 and the Kosai Plant in 2022, and intend to continue installing solar power facilities at other plants in the future.

Suzuki has also installed two wind power generation facilities at the Kosai Plant and one at its training center.

At overseas plants, Maruti Suzuki India Limited, Suzuki Motor Gujarat Private Limited, and Suzuki Motorcycle India Private Limited have introduced and are further expanding solar power generation facilities.

We will actively promote the use of renewable energy, both in Japan and overseas.

Amount of renewable energy (amount of CO2 reduced)

Electric power generated by renewable energy

| Electric power generation (MWh) | |

|---|---|

| Solar power generation (Makinohara, Hamamatsu Plant, Maisaka, Iwata Plant, Kosai Plant) | 40,561 |

| Solar power generation (Maruti Suzuki India, Suzuki Motor Gujarat, etc.) | 30,941 |

| Wind power generation (Kosai Plant, training center) | 1,404 |

| Small-scale water power generation (Kosai Plant) | 68 |

TopicsSuzuki introduces CO2-free renewable energy-derived electricity at head office and domestic plants

As part of its efforts to achieve carbon neutrality, Suzuki Motor Corporation (Suzuki) has gradually introduced Shizuoka Green Electricity*, CO2-free renewable energy-derived electricity, for use at its head office and plants in Shizuoka Prefecture, starting in July.

As a result, all Suzuki sites in Shizuoka Prefecture will use CO2-free electricity, resulting in zero CO2 emissions from electricity use.

In addition, Suzuki Group companies (see table to the right) have also introduced CO2-free electricity.

Based on the target date set by the government, Suzuki aims to achieve carbon neutrality by 2050.

After the introduction of CO2-free electricity, we will continue to vigorously reduce electricity, gas, and other energy used in our business activities, as well as promote the conversion to renewable energy to become carbon neutral.

We will continue to work towards carbon neutrality throughout the entire Group, including other domestic and overseas bases, in order to realize a sustainable society and sustained growth in our corporate value.

* Electricity generated from virtually 100% renewable energy sources by utilizing environmental value derived from hydroelectric power generation, solar power generation, and other sources.

This is a service of Chubu Electric Power Miraiz Co., Inc. that utilizes environmental and local value derived from renewable energy sources such as hydroelectric power plants located in Shizuoka Prefecture to supply electricity with zero CO2 emissions produced in Shizuoka Prefecture.

Main facilities introducing CO2-free electricity

| Suzuki | Head office, Kosai Plant, Iwata Plant, Sagara Plant, Osuka Plant, Hamamatsu Plant (motorcycle plant, Motorcycle Technical Center), parts plant, Tooling Dept., Marine Technical Center, Ryuyo Proving Grounds, Sagara Proving Grounds |

|---|---|

| Suzuki Group companies | Hamamatsu Plant of Suzuki Auto Parts Mfg. Co., Ltd., Kosai Plant, Ryuyo Pipe Plant, Iwata Pipe Division and Sagara Plant of Snic Co., Ltd., Kosai Plant and Sagara Plant of Suzuki PDC |

Efforts in office activities, etc.

Efforts at data centers

At Suzuki’s data center, energy-saving facilities are being introduced to reduce the amount of power consumption which increases every year.

●Conversion to energy-saving equipment and improvement of cooling efficiency

Since 2017, we have been systematically and sequentially shifting the air conditioners in server rooms to high-efficiency models such as the inverter type, and completed the replacement of all air conditioning equipment in 2022. As a result, we reduced our annual power consumption in 2022 by 960,000 kWh compared to 2017 (over 40% reduction in power consumption of air conditioning equipment).

In 2023, we installed a new containment system that physically isolates server waste heat from air conditioned cold air. We replaced the existing uninterruptible power supply with ones that have lower power loss. It is expected to reduce annual power consumption by 220,000 kWh in total.

Efforts at offices

We determined the guidelines for energy saving action in FY2008, and promote energy saving at offices and the reduction of CO2 emissions through a group effort involving all employees.

●Guidelines for energy saving action

We have established a guideline for energy saving action as a part of In-house Cost Cutting Activities, which covers a wide range of activities, for the purpose of promoting energy saving (CO2 reduction) by individual employees.

[Guidelines for In-house Cost Cutting Activities (Excerpt)]

- (1) Follow the predetermined temperature settings of air conditioners (cooling at 28°C and warming at 20°C)

- (2) Turn off unnecessary lights

- (3) Save electricity of electrical appliances

- (4) Implement eco-driving

- (5) Computerize documentary forms and minimize printouts of electronic data

●Introduction of energy-saving facilities

We have been promoting the introduction of LED lighting since FY2012 to promote energy saving at offices. So far, we have changed up to approximately 80% of the lights in offices to LED.

Other efforts

●Reduction of traveling by utilizing IT

We are making efforts in reducing energy consumption from traveling by proactively utilizing a TV conference system, web conference system, and remote work environment.

Suzuki expanded the scope and scale of its remote work environment for partner companies, and enabled employees at partner companies to engage in their tasks without having to come to work at Suzuki, which helped reduce energy consumption from PCs and air conditioners, etc.

Reduction of the number of people traveling: Monthly average number of users: 4,779 people Average number of people per work day: 208 people.

* The above figures are based on results from March 2023

●Promotion of eco-driving

We started eco-driving education in FY2007 as part of our environmental education programs, and since FY2009, we have held seminars focusing on eco-driving at the head office and each plant/office on an as-needed basis. By March 2023, a total of 15,122 people have participated in the seminar.

Efforts at non-manufacturing subsidiaries and sales distributors

Our 4 non-manufacturing subsidiaries and 56 sales distributors* in Japan work to save energy in business activities under a common energy-saving goal to “Aggressively promote energy-saving activities toward suppressing global warming by introducing electricity savings and energy-saving facilities.” Also, each of our 54 domestic automobile sales distributors have introduced the Environmental Management System. These companies carry out efforts aimed at saving energy and water, reducing waste through a PDCA cycle, and adhering to environmental laws and regulations.

Goal:

Aggressively promote energy-saving activities toward suppressing global warming by introducing electricity savings and energy-saving facilities

- * 4 non-manufacturing subsidiaries: Suzuki Transportation & Packing Co., Ltd., Suzuki PDC, Suzuki Business Co., Ltd., and Suzuki Engineering Co., Ltd.

56 sales distributors: 54 affiliate automobile sales distributors in Japan including Suzuki Motor Sales Tokyo Inc., as well as Suzuki Motorcycle Sales Inc. and Suzuki Marine Co., Ltd.

JapanDomestic sales distributors

●Promoting energy savings

We maintain an active awareness of energy savings on a daily basis, such as by efficiently using the air conditioners, lighting and information equipment within stores, and by promoting eco-driving through travel between store locations or to business partners using company-owned cars and commercial vehicles.

Promoting Cool Biz

Suzuki Motor Sales Okinawa Inc.

Visualization of electricity usage

Suzuki Motor Sales Okinawa Inc.

●Efforts using IT

We use IT such as the internet as a tool in business discussions with customers and communication among employees. We make effective use of customers’ and employees’ time and reduce the burden of travel, while working to reduce energy consumption and CO2.

Establishing an online sales location Suzuki Motor Sales Shimane Inc.

Suzuki Motor Sales Tokai Inc.

Holding online meetings

Suzuki Motor Sales Kagoshima Inc.

●Environmentally friendly store designs

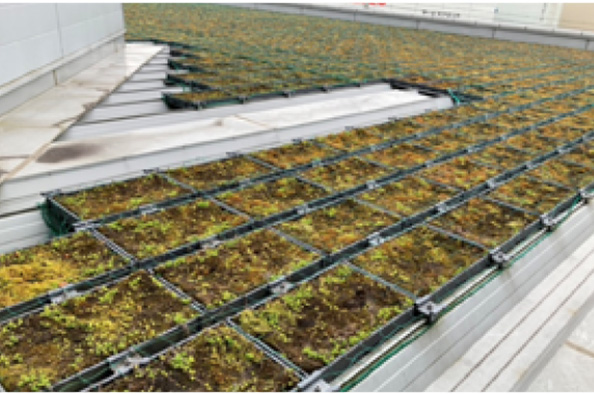

We promote the installation of energy-saving devices such as LED lighting equipment and high-efficiency air conditioners at stores. We work to create environmentally friendly stores by, for instance, greening the roofs and installing solar panels on some stores.

Installing solar power generation equipment

Suzuki Motor Sales Shimane Inc.

Rooftop greening

Suzuki Motor Sales Shiga Inc.

Efforts in the supply chain, etc.

Efforts in procurement

Efforts in the supply chain toward carbon neutrality

To achieve carbon neutrality (net zero CO2 emissions) by 2050, it is essential to reduce CO2 emissions in the supply chain, which accounts for approximately 90% of the CO2 emissions from manufacturing.

Suzuki has been working toward carbon neutrality in its supply chain since 2021. In 2022, we established a dedicated department and began to calculate the CO2 emissions of each business partner by fiscal year and by component in order to gain a detailed understanding of their CO2 emissions.

In addition, to achieve carbon neutrality by 2050, we have asked our business partners to create CO2 emission reduction targets and roadmaps for 2030, and have begun reduction activities such as confirming the feasibility of reduction items. We cooperate with our business partners by visiting their manufacturing sites to confirm on-site examples of improvement initiatives, share Suzuki’s goals and examples of improvement, identify issues, and listen to their problems.

Efforts in domestic transportation

We are trying to reduce transportation distance, improve transportation efficiency, promote modal shift, increase fuel efficiency of transportation vehicles, etc. in order to reduce CO2 emissions in domestic transportation.

CO2 emissions in FY2022 were reduced by 4% compared to FY2016 and increased by 9% compared to the previous year, to 37,694 t-CO2.

CO2 emissions per sale improved by 28% compared to FY2016.

Trends in CO2 emissions from domestic transportation

●Modal shift of a portion of truck transportation to rail transportation

We have reduced CO2 emissions through the modal shift of some of our regular freight transportation services from trucks to rail, which is more energy-efficient, for transportation from factories to distant transportation bases.

●Modal shift of a portion of truck transportation to ship transportation

In December 2022, we newly established and began operation of the Suzuki Parts Center Tomakomai. By reviewing the conventional transportation of parts and accessories to Hokkaido and establishing a new transportation base to consolidate transportation, we have achieved a modal shift to marine transportation for approximately 80% of the transportation distance from the parts plant (Kosai City, Shizuoka Prefecture) to Tomakomai, reducing CO2 emissions by approximately 73%.

TopicsSuzuki promotes modal shift to reduce CO2 emissions

Suzuki has introduced new 31 ft containers for rail transportation in order to reduce CO2 emissions in the transportation of parts and accessories. The containers will be owned by Suzuki and used for transportation to Suzuki Parts Center Fukuoka.

Previously, parts and accessories were being transported to Suzuki Parts Center Fukuoka by large trucks and 12 ft containers for rail transportation.

However, large truck transportation had its challenges, such as higher CO2 emissions than rail transportation, and 12 ft containers for rail transportation had a lower loading capacity than large trucks.

The introduction of 31 ft containers for rail transportation will stabilize rail transportation, secure loading capacity, and reduce CO2 emissions by approximately 80% compared to large truck transportation.

In addition, Suzuki newly established and began operation of the Suzuki Parts Center Tomakomai in December 2022.

By reviewing the conventional transportation of parts and accessories to Hokkaido and by using marine transportation for approximately 80% of the distance from the parts plant (Kosai City, Shizuoka Prefecture) to Tomakomai, CO2 emissions have been reduced by approximately 73%.

Suzuki Parts Centers are wide-area parts centers managed and operated by Suzuki that supply genuine parts and accessories for Suzuki automobiles.

Currently, six such centers are located throughout Japan, from which parts and accessories are quickly supplied to distributors and dealers in each prefecture. By enhancing the delivery speed of parts and accessories, we are striving to improve customer satisfaction as well as improve the efficiency of service operations at distributors and dealers.

With the aim of achieving carbon neutrality by 2050, Suzuki will promote a modal shift to reduce CO2 emissions.

<Reference>Other initiatives in parts transportation

Improvement of KD packaging materials

By replacing conventional steel materials with cardboard for automobile seat transportation fixtures for export overseas, we have reduced CO2 emissions during manufacturing by approximately 91%.

This initiative won the Minister of Economy, Trade and Industry Award, the highest award in the 2022 Japan Packaging Contest. It also won the WorldStar Award in the WorldStar Competition 2022 sponsored by the World Packaging Organisation (WPO).

31 ft container for rail transportation

Japan

Japan