| Suzuki Environmental Vision 2050 | Milestone 2030 | |

|---|---|---|

| Air conservation | Minimize air-polluting substances emitted from business activities and products by 2050 | By 2030:

|

Basic concept

Suzuki has been promoting air conservation initiatives, including the introduction of low-emission vehicles suited to each country’s situation. As our main markets are in emerging countries such as India and Southeast Asian countries, we would like to make a larger contribution. For example, by promoting activities to generate and procure electricity derived from renewable energy sources on our own, we will not only reduce global CO2 emissions but also contribute to the conservation of the atmospheric environment in the regions in which we operate. In addition, we will introduce powertrains that are suited to the energy and infrastructure situations of each sales country and region from the perspective of product life cycles, as well as strive to reduce volatile organic compounds (VOCs) from production and other processes.

Efforts in product use

Calculation of air-polluting substance emissions of products using Life Cycle Assessment (LCA)*

Suzuki conducts LCA not only on CO2 but on other airpolluting substances as well.

For example, Suzuki was successful in reducing NOx and SOx emissions in the driving stage of its new Solio (hybrid) model, but in the course of replacing steel with aluminum to reduce material weight, SOx and NOx emissions increased in other LCA stages.

Suzuki will continue its initiatives to reduce substances as well as CO2.

- * Life Cycle Assessment: A method of evaluating a product as a whole by calculating its potential environmental impact at each stage of its life cycle, from raw material processing to disposal. Evaluation results are displayed as an index to confirm the relative environmental improvement effect.

Suzuki LCA Stages

- * Life Cycle Assessment: A method of evaluating a product as a whole by calculating its potential environmental impact at each stage of its life cycle, from raw material processing to disposal. Evaluation results are displayed as an index to confirm the relative environmental improvement effect.

Ratios of air-polluting substance emissions

Example: Solio (installed with Mild Hybrid) (ratio of NOx emissions with the previous model as 100%)

A: Installed with Mild Hybrid (Launched in December 2020)

B: Installed with Hybrid (Launched in December 2022)

NOx: Nitrogen Oxide

SOx: Sulfur Oxide

PM: Particulate Matter

NMHC: Non Methane Hydrocarbons

Efforts in design and development

Efforts in emission gas reduction

●(Automobiles) Reducing hazardous elements within emission gas

In order to satisfy emission regulations that are getting more stringent all over the world, Suzuki has been improving engine combustion technologies as well as promoting improvement in the emission purification performance. From the view of preserving resources, we are making efforts to reduce the precious metals and rare earth elements used for catalysts.

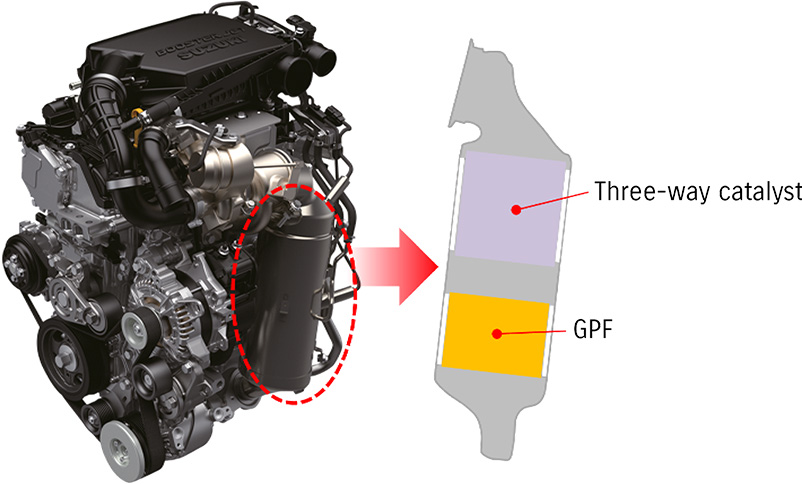

We are making efforts to clean emission gas throughout the world by adopting purification technologies that meet the needs of each market, such as a zone-coated catalyst that concentrates precious metals effective for the purification performance in cold engine starts at the front section of the catalyst, a catalyst that suppresses heat deterioration, and a gasoline particulate filter (GPF) that removes PM (particulate matter) from direct-injection turbo engines.

K14D engine

Cleans emission gas by collecting PM (particulate matter) contained in exhaust gas

●(Motorcycles) Reducing emission gas

We are striving to reduce emission gas by complying with the Euro5 standards and the 2020 domestic emission gas regulations.

The new V-STROM 800DE launched in March 2023 meets the domestic emission regulations for 2020 by adopting a compact combustion chamber with a comparatively long stroke, where a short stroke is usually used due to narrow space, and optimizing cam profile, ignition timing and catalyst.

New V-STROM 800DE

●(Outboard motors) Reducing emission gas

Suzuki’s four-stroke outboard motors satisfy the 2008 emission gas regulation values set by the California Air Resources Board (CARB), the secondary regulation values set by the U.S. Environmental Protection Agency (EPA), and the 2011 marine engine emission voluntary regulation values (secondary regulation) set by the Japan Marine Industry Association.

Efforts in reducing chemical substances

●Reducing VOCs (Volatile Organic Compounds)*1 in the cabin

In order to provide safe and secure products to customers, we are making efforts in reducing cabin VOCs by using materials, bonding agents, etc. that emit less VOCs for automobile interior parts. For all new domestic automobile models sold since January 2006, we have successfully achieved lower cabin VOC levels than the target set by the automobile industry*2. In FY2022, we achieved the target for models including the Solio Hybrid and Spacia BASE. We are also taking the lead in responding to new regulations that are being considered in Europe for the future.

In addition, we are making efforts in reducing odors from interior parts and reducing cabin odor to promote a more comfortable cabin environment.

Measuring VOC inside a Solio Hybrid

- *1 VOCs are deemed to be a cause of sick building syndrome (bringing about a headache and/or sore throat) and has been gaining attention for its impact on health.

- *2 Japan Automobile Manufacturers Association (JAMA) has been making voluntary efforts in new passenger car models sold from April 2007 and new commercial vehicle models sold from April 2008 to satisfy the guideline values for vehicle cabin VOCs on substances defined by Japan’s Ministry of Health, Labour and Welfare in 2002.

Efforts in reducing noise

●(Motorcycles) Reducing noise

Suzuki motorcycles meet noise regulations, such as the FY2016 regulation in Japan, UN R41-04 in Europe, and 40 CFR Part 205 in the United States.

Product example

The following describes our noise regulation efforts, taking the new V-STROM 800DE as an example.

To comply with the latest domestic noise regulations, the new V-STROM 800DE adopts many structures with high noise reduction performance while also being designed to minimize weight increase.

①The air cleaner has sufficient capacity and reduces intake noise and by rib placement and rigid shape, reduced radiated noise from wall surfaces.

②The muffler is composed of a main silencer and a sub silencer; it has sufficient capacity and a structure which can achieve favorable noise eliminating performance. By mounting glass wool on the inner wall, we improved damping performance and reduced radiated noise from wall surfaces.

Efforts in business activities

Efforts in production

Efforts in reducing emission gas

●Control of SOx and NOx emissions

In order to prevent air pollution, we are making efforts to maintain and control SOx (sulfur oxides) and NOx (nitrogen oxides) emissions from boilers, etc. by setting voluntary standards that are stricter than the regulation values.

SOx emissions*

* SOx emissions are calculated based on fuel consumption from January to December.

[Scope of aggregation]

Iwata Plant, Kosai Plant, Osuka Plant, Sagara Plant, Hamamatsu Plant, former Takatsuka Plant (until July 2018), former Toyokawa Plant (until July 2018), and the Tooling Dept.

NOx emissions

[Scope of aggregation]

Iwata Plant, Kosai Plant, Osuka Plant, Sagara Plant, Hamamatsu Plant, former Takatsuka Plant (until July 2018), former Toyokawa Plant (until July 2018), and the Tooling Dept.

Efforts in reducing chemical substances

●VOC reduction in the painting process

We are working to reduce emissions of VOC solvents used in the painting process.

The Suzuki Environmental Plan 2025 targets reducing VOC emissions per painted area by 50% or more compared to FY2000 in the painting process at plants in Japan.

In FY2022, total emissions from painting car bodies, bumpers and motorcycles were 3,560 tons/year. VOC emissions intensity was 46.1 g/m2, a 38.4% reduction compared to FY2000, but falling short of the targeted 40% decrease. The reason for not reaching the target was an increase in the number of car models with high paint usage, which was caused by a change in the sales composition.

We plan to achieve the targets of the Suzuki Environmental Plan 2025 by further improving painting methods and reducing VOC emissions as well as by expanding use of water-based paints when the painting process is renewed.

VOC emissions in the painting process

[Scope of aggregation]

Domestic plants with each painting process of automobile body, motorcycle, and bumpers (Iwata Plant, Kosai Plant, former Toyokawa Plant (until FY2018), Hamamatsu Plant, and Sagara Plant)

Efforts in reducing odor and noise

Although we strictly follow the relevant regulations and laws, odors and noises may still make local residents uncomfortable. Compliance with the laws and regulations, which is the basis of sustainability, is the minimum responsibility. Aiming for plants that are trusted by the local community, we will continuously promote necessary measures for the prevention of noise and odor and the elimination of their potential sources.

Japan

Japan