Japan

Japan

Japan

Japan

GLOBAL NEWS

9 September 2025

Suzuki Announces Technology Strategy 2025 for 10 Years Ahead

In February this year, Suzuki announced its new mid-term management plan, setting the vision of “Team Suzuki as infrastructure mobility closely connected to daily life” and adopting the corporate slogan “By Your Side.”

The Technology Strategy 2025 builds on Suzuki’s traditional efforts to address environmental and energy challenges and expands its focus to actively tackle social issues related to people’s mobility through Suzuki’s technologies.

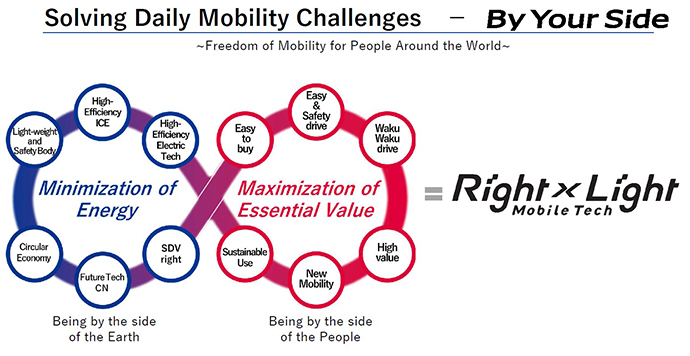

As a company providing infrastructure mobility closely linked to daily life, Suzuki has newly established the concept of “3Gen・2Gen (Genba, Genbutsu, Genjitsu, Genri, Gensoku)*”, adding “Fundamental Principle (Genri), Fundamental Rule (Gensoku) (2Gen)” to the traditional philosophy of conduct “Actual Place, Actual Thing, Actual Situation (Genba, Genbutsu, Genjitsu) (3Gen)”. Based on the technology philosophy of “Minimizing Energy” in harmony with the Earth and the technology policy of “Maximizing Essential Value” centered on people, Suzuki will offer technologies under the concept of “Right x Light Mobile Tech”, delivering value that truly supports customers.

- *Genba, Genbutsu, Genjitsu, Genri, Gensoku:

Actual Place, Actual Thing, Actual Situation, Fundamental Principle, Fundamental Rule

Key Initiatives of Technology Strategy 2025

● Lightweight and Safe Vehicle Bodies

Suzuki will further evolve its safe and lightweight “HEARTECT” platform. In pursuit of minimizing energy through weight reduction technologies, Suzuki set a goal last year to reduce vehicle weight by 100kg. To learn from the wisdom of predecessors, Suzuki studied past models, and through cross-departmental activities between the motorcycle and automobile divisions, has identified a path to achieve approximately 80kg of weight reduction. Moving forward, while ensuring performance, Suzuki will pursue overall optimization to achieve the “just-right” balance, meticulously refining every component and even every bolt, aiming to achieve the target.

● Efficient ICE and CNF Technologies

(ICE: Internal Combustion Engine, CNF: Carbon Neutral Fuel)

The “Super Ene-Charge” system announced last year is being developed as a hybrid system that leverages lightweight vehicle bodies, and it is expected to achieve the targeted performance. In addition, Suzuki is refining its high-speed combustion and low-friction technologies cultivated through years of engine development, and is applying them horizontally to develop new high-efficiency engines.

Regarding carbon-neutral fuel vehicles, mass production of the motorcycle “GIXXER SF 250 FFV*” began in India in January this year, and Suzuki has adapted various automobile models to E20 fuel. Development is also underway to introduce automobile models equipped with FFV* engines within this fiscal year.

- *FFV: Flexible Fuel Vehicle

● Battery-Lean BEV/HEV (Battery Electric Vehicle/Hybrid Electric Vehicle)

Embodying Suzuki’s action principle of “Sho-Sho-Kei-Tan-Bi (Smaller, Fewer, Lighter, Shorter, Beauty)”, Suzuki is developing electrified vehicles with minimized energy consumption, featuring compact and efficient electric units and small, lightweight batteries. The new “e VITARA,” Suzuki’s first battery electric vehicle, is the first model in this series. It combines advanced EV technology with the robust character of an SUV, offering a battery-lean BEV with a well-secured driving range.

In motorcycles, the “e-ACCESS” announced in India is also planned for launch in various countries as a battery-lean, just-right EV scooter.

● SDV Right (SDV: Software Defined Vehicle)

Suzuki defines SDV Right as a means to realize “just-right” high-performance electrical components for its customers. The concept was applied starting with the new “e VITARA,” equipping the B-segment SUV with functions Suzuki considers just right for customers. Suzuki will continue to carefully select and equip valuable electrical components with just-right functions across its model lineup.

● Easy-to-Disassemble Design for Recycling

Suzuki is advancing not only product designs that are easy to disassemble for recycling and reuse but also weight reduction of resin parts in collaboration with the “S Light Project” for lightweight design, material unification to promote recycling, and mono-material designs that require no disassembly. Recycling material utilization technologies, including the use of recycled plastics, are also evolving and will be introduced sequentially into products.

Initiatives Toward Carbon Neutrality

● Team Suzuki CN Challenge

The "Team Suzuki CN Challenge," which participated again this year in the Suzuka 8 Hours Endurance Road Race, is composed entirely of Suzuki employees except for the riders. Alongside technological development based on the philosophy of minimizing energy consumption to realize a carbon-neutral society, the team fosters employees' motivation to take on challenges and creates strong teamwork. The motorcycle is equipped with components made from sustainable materials including tires, oil, fairings, and brakes, and this year, the team also challenged themselves by using 100% sustainable fuel. Moving forward, we will continue to promote sustainability initiatives, including exploring the potential for reducing environmental impact through racing.

● Biogas Business

In July this year, Suzuki’s biogas business was selected for an industrial cooperation program by the United Nations Industrial Development Organization (UNIDO). The biogas plant currently under construction will begin operations sequentially from 2025. The biogas supplied can be used as fuel for CNG vehicles, which account for about 20% of the passenger car market in India, contributing to greenhouse gas emission reduction. In addition to improving energy self-sufficiency and creating new employment, the project will also enhance rural income, living standards, and productivity through the purchase of cow dung and the production of organic fertilizer from it.

Following this selection, Suzuki will continue efforts to build new biogas plants incorporating Japanese technology.

● Suzuki Smart Factory

In the production domain, Suzuki is advancing the “Suzuki Smart Factory” project to realize a carbon-neutral society. By utilizing digital technologies to visualize operations, Suzuki is improving quality and productivity while reducing energy consumption. The new painting plant at the Kosai Plant, which started operation in June this year, has significantly reduced energy consumption through these initiatives.